We provide quality products and services to customers from all over the world.

How Technology Is Changing Solid Door Manufacturing Processes

The manufacturing of solid doors has seen significant transformations over recent years, driven largely by advancements in technology. Solid door manufacturers are increasingly adopting new tools and methods to improve efficiency, product quality, and customization options. These technological changes are reshaping traditional production lines and allowing manufacturers to meet evolving market demands more effectively.

One of the primary ways technology is impacting solid door manufacturing is through automation. Automated machinery has replaced many manual tasks, enabling faster production speeds while maintaining consistent quality. For example, computer numerical control (CNC) machines are widely used to cut and shape door components with precision. This technology reduces human error and allows manufacturers to produce complex designs that were previously difficult to achieve. As a result, solid door manufacturers can offer more diverse styles without compromising on craftsmanship.

In addition to automation, the use of advanced software plays a crucial role in modern solid door manufacturing. Design software allows manufacturers to create detailed 3D models and prototypes before any physical work begins. This helps identify potential design flaws and optimizes the use of materials, reducing waste. By integrating design and production systems, solid door manufacturers can streamline workflows and reduce turnaround times. Customers also benefit from this technology, as they can visualize custom doors before committing to a purchase.

Material technology has also evolved alongside manufacturing processes. Solid door manufacturers now have access to improved materials that enhance durability, insulation, and aesthetics. For instance, composite materials and engineered wood are increasingly used in place of traditional hardwood to offer cost-effective and environmentally friendly options. These materials often require different handling and finishing techniques, which modern technology helps facilitate. With better material options, manufacturers can cater to a broader range of customer preferences and environmental standards.

Another notable change in solid door manufacturing is the implementation of quality control technologies. Sensors and real-time monitoring systems can detect defects or inconsistencies during production. This proactive approach helps manufacturers address issues early, ensuring that only doors meeting specific standards reach customers. Automated inspection systems can also provide detailed reports on each product, supporting traceability and accountability in the manufacturing process.

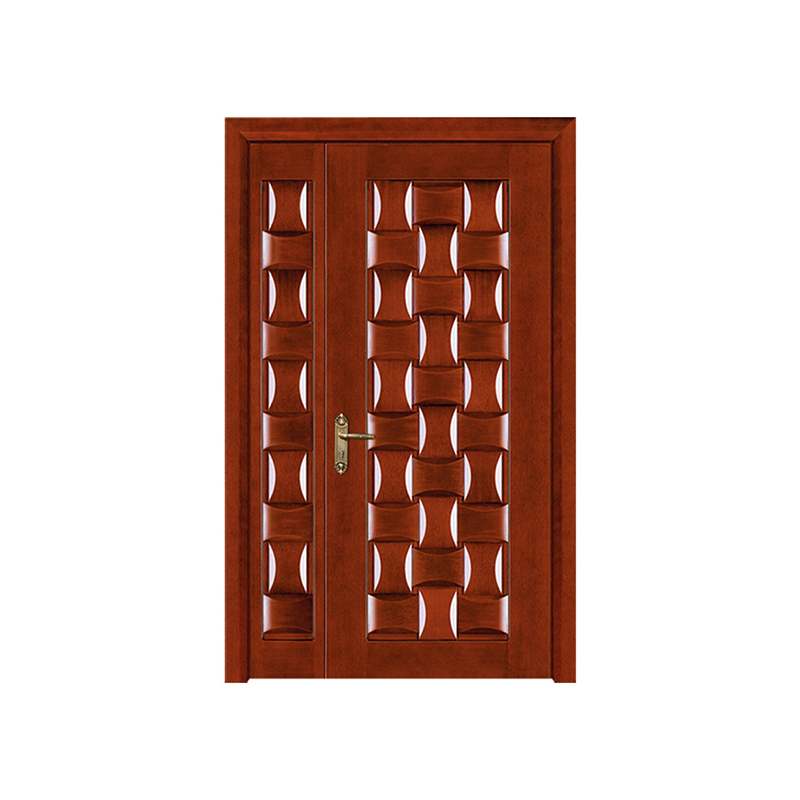

Furthermore, technology has improved the customization capabilities of solid door manufacturers. Digital printing and laser engraving technologies enable detailed and precise decorative patterns on door surfaces. These technologies allow for unique finishes and personalized designs without significantly increasing production time or cost. This flexibility appeals to both residential and commercial customers seeking doors that match specific architectural or branding requirements.

Sustainability has become an important consideration in solid door manufacturing, and technology supports efforts to minimize environmental impact. Efficient production techniques reduce waste, and modern machinery often consumes less energy than older equipment. Additionally, some solid door manufacturers are exploring the use of renewable energy sources and recycling programs within their facilities. Technology helps track resource use and implement greener practices throughout the production cycle.

Technology is transforming solid door manufacturing in multiple ways. Automation, advanced design software, new materials, quality control systems, enhanced customization, and sustainability efforts are all contributing to improved processes and products. Solid door manufacturers that adopt these technologies can respond more effectively to customer needs and market trends. As technology continues to advance, it is likely that solid door manufacturing will become even more efficient, innovative, and environmentally responsible in the years to come.

Interested in cooperation or have questions?

![]() +86-13857003056

+86-13857003056

![]() No. 27 Lianhuashan Avenue, Jiangshan Economic Development, Jiangshan, Quzhou, Zhejiang, China

No. 27 Lianhuashan Avenue, Jiangshan Economic Development, Jiangshan, Quzhou, Zhejiang, China

English

English русский

русский Français

Français Español

Español عربى

عربى